- +91 96876 39980

Pharmaceutical Glass Vials:

Welcome to Atom Industries is a leading Supplier of Glass Ampoules and Vials for pharmaceutical and healthcare industry. These vials are manufactured from Type 1 Class A Borosilicate glass Also Cosmetics & Agriculture Industries...Pharmaceutical glass vials is a type of an ideal pharmaceutical package material in pharmaceutical field. Modules & tubular pharmaceutical glass vials. After the glass container molding is completed.

We Provided Ceramic Screen Printing on various decorations, logo, manufacturers- Expire date, patterns, and symbols can be added to the surface with the help of different container treatment processes. Adding these decorative finishes give glass containers a unique, sophisticated and premium look, giving more value to your product. Treatment processes used are dependent on the decoration and finish the customer requires.

We also do Ceramic Printing on our Glass Ampoules and Vials as per Customer's needs.

Applications :

- Pharmaceutical glass vials is widely used for filling little injectable medicine.

- Lyophilized in pharmaceutical field.

- tubular pharmaceutical glass vials is characterized by easy to use for nurse and doctor

- Injection & Infusion Products

- Pharmaceutical liquids

- Cosmetic Packaging & Displays

- Perfume bottles

- powders or capsules Medication Management

- Pharmacy bottles

Work with Atom industries, Leading Supplier of Customise Glass Vials

Our offered pharmaceutical glass vial consists of tubular type and moulded type and it can be used for different purposes: injectable vials also Our glass vials are custom-fit to contain any Pharmaceutical or cosmetic product while retaining their overall quality. Combining their heavy weight and rigid structure, our glass vials do not deform in shape when exposed to any temperatures and can be held easily by your customers…

Available in various sizes 1ml, 2ml, 5ml, 7ml, 10ml, 20ml in order to meet different client’s requirement and has gained multiple times buyback from customer. As we Are Provides premium glass vial supplier, ATOM produces glass vials annually to meet global demand. We achieve this vast quota through our efficient processing of premium glass our control over production translates to faster lead times and lower costs on your end. Pharmaceutical Glass Vials have various sizes and shapes for different uses like storing pharmaceutical liquids, powders or capsules. Both clear and amber glass vials are available. Clear glass vial is suitable for most pharmaceuticals with a high ultraviolet transmission.

Technical Specifications :

| Name | Pharmaceutical glass vial/ Cosmetics Glass Vials Pharmaceutical clear tubular glass vial /Medical tubular amber glass vial Tubular clear glass vial/tubular clear injection glass vial / medical injectable glass vial |

| Printing way | Ceramic colors screen printing |

| Size | 2ml, 5ml, 7ml, 10ml, 15ml, 20ml, 30ml in accordance with customer request. |

| Shape | Round shape |

| Application | Pharmaceutical, Personal Care, Cosmetic. Etc…. |

| Style | Various sizes for your choice |

| Supply Ability | Customised |

Advantages of Pharmaceutical glass bottle printing

As we’ve mentioned, screen printing on glass containers is an excellent way to give your products a look that draws the consumer’s eye and attention. Other benefits include: ATOM, Ceramic Colors with produces packaging for makers of beautiful products. We help bring your branding to life, making your products stand out in crowded markets. Our screen printed glass technology allows us to print directly on the Pharmaceutical Glass Ampoules and Vials bottles on your product, for a look that can’t be replicated any other way,

- Permanent printing that can’t be removed and are waterproof.

- Bottles/containers must be cylindrical or flat sided; oval shapes won't work. (Like Ampoules, Vials, Perfumes Bottles, and Cosmetics etc...)

- They may be tapered, however, with the top being larger than the bottom, or vice versa.

- Bottles/containers must have a smooth and even surface to print on.

| Reference | Overflow Capacity | Height (MM) | Standard Neck-Finish (MM) | Body Diameter (MM) | Body Wall Thickness |

|---|---|---|---|---|---|

| 2R | 4 | 35 | 13 | 16 | 1 |

| 4R | 6 | 45 | 13 | 16 | 1 |

| 6R | 10 | 40 | 20 | 22 | 1 |

| 8R | 11.5 | 45 | 20 | 22 | 1 |

| 10R | 13.5 | 40 | 20 | 24 | 1 |

| 15R | 19 | 60 | 20 | 24 | 1 |

| 20R | 26 | 55 | 20 | 30 | 1.2 |

| 25R | 32.5 | 65 | 20 | 30 | 1.2 |

| 30R | 37.5 | 75 | 20 | 30 | 1.2 |

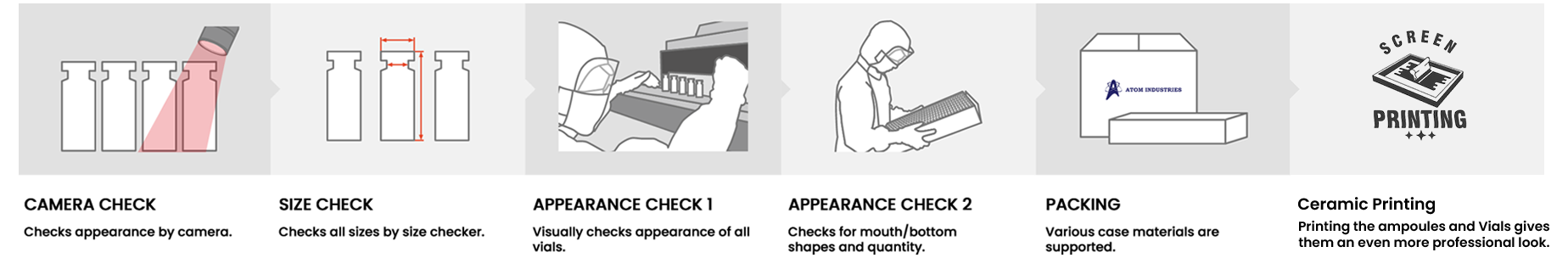

Vial Check Processes :-